Die Herausforderung: Sichere Überbrückung von OT und Cloud

Für diesen Fortune-100-Hersteller stand viel auf dem Spiel. Jedes Werk verbraucht jährlich Energie und Wasser im Wert von Millionen von Dollar, und selbst kleine Leistungsschwankungen der Anlagen können die Kosten in die Höhe treiben. Ungeplante Ausfälle waren sogar noch schwerwiegender, denn jede Stunde Ausfallzeit bedeutete Umsatzeinbußen und unterbrochene Lieferketten.

Die Verantwortlichen sahen eine klare Lösung: die Einbindung von Betriebsdaten in leistungsstarke Cloud-Analyseplattformen von Drittanbietern. Mit Echtzeit-Einblicken konnten die Wartungsteams Ausfälle vorhersagen, bevor sie eintraten, kritische Reparaturen priorisieren und die Ressourcennutzung in allen Anlagen optimieren.

Doch was wie ein unkomplizierter Plan zur digitalen Transformation aussah, stieß schnell auf Hindernisse. Die IT-Sicherheitsteams des Unternehmens äußerten dringende Bedenken. Der direkte Anschluss älterer OT-Systeme an das Internet würde diese einer Vielzahl von Cyberrisiken aussetzen. Viele dieser Geräte verfügten nicht über moderne Sicherheitsfunktionen oder die Möglichkeit, Patches zu installieren, was sie besonders anfällig machte. Ein einziger ungeschützter Datenfeed könnte einen gefährlichen Einstiegspunkt für Ransomware oder staatlich gesponserte Angreifer darstellen.

Gleichzeitig war es keine Option, die Produktionssysteme zu modifizieren oder zu ersetzen, um sie an die moderne Konnektivität anzupassen. Die Risiken von Ausfallzeiten und Kostenüberschreitungen waren zu hoch. Das Unternehmen brauchte eine Möglichkeit, die Tür zur Cloud zu öffnen, ohne dabei die Integrität seiner Produktionsnetzwerke zu gefährden.

Wir brauchten eine Möglichkeit, Echtzeit-Fabrikdaten in die Cloud zu bringen, ohne unsere Produktionssysteme Cyber-Risiken auszusetzen. OPSWAT bot uns dieses Gleichgewicht aus Transparenz und Sicherheit.

Direktor für OT Security

MetaDefender Optical Diode (Fend) mit Cloud

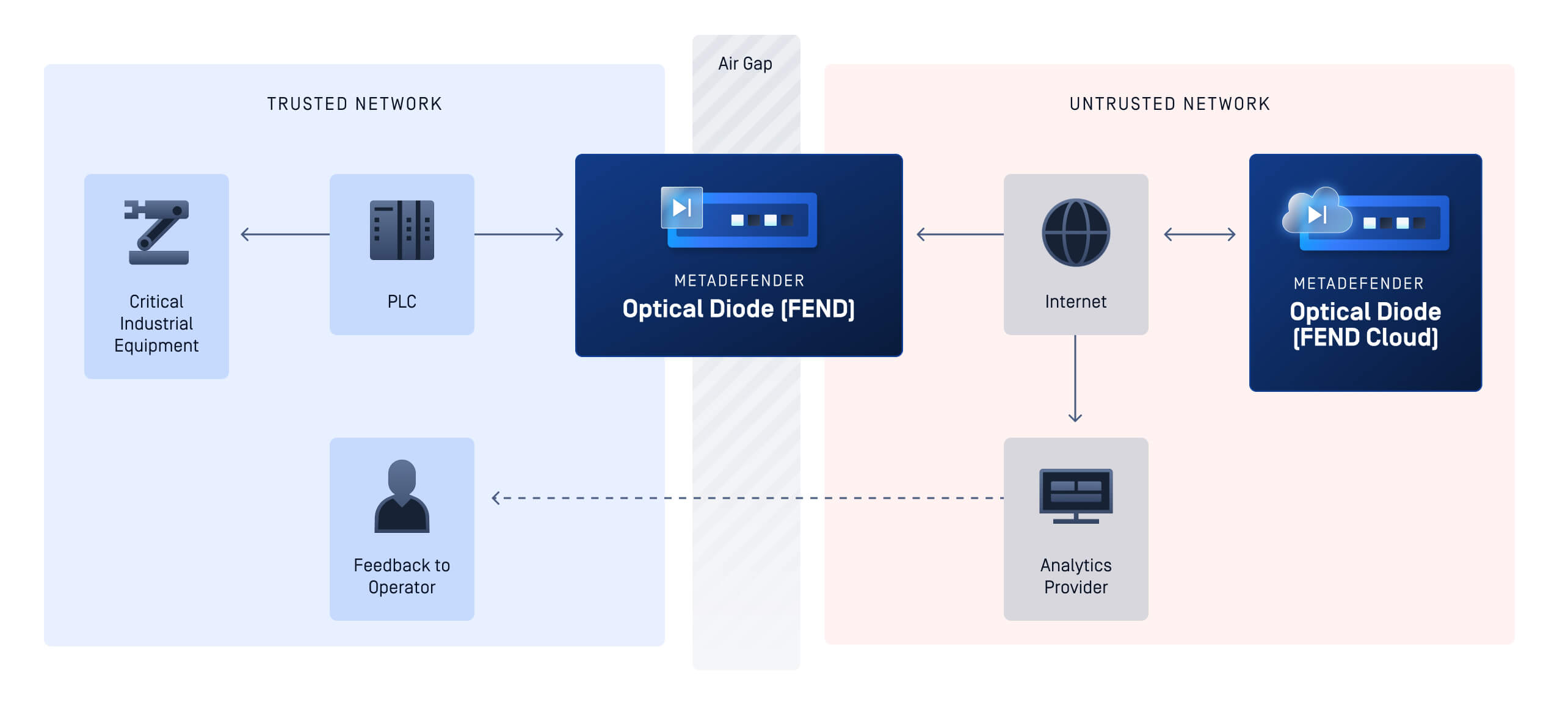

Der Hersteller setzt ein MetaDefender Optical Diodeeine sichere AWS-basierte Ingestion-Plattform.

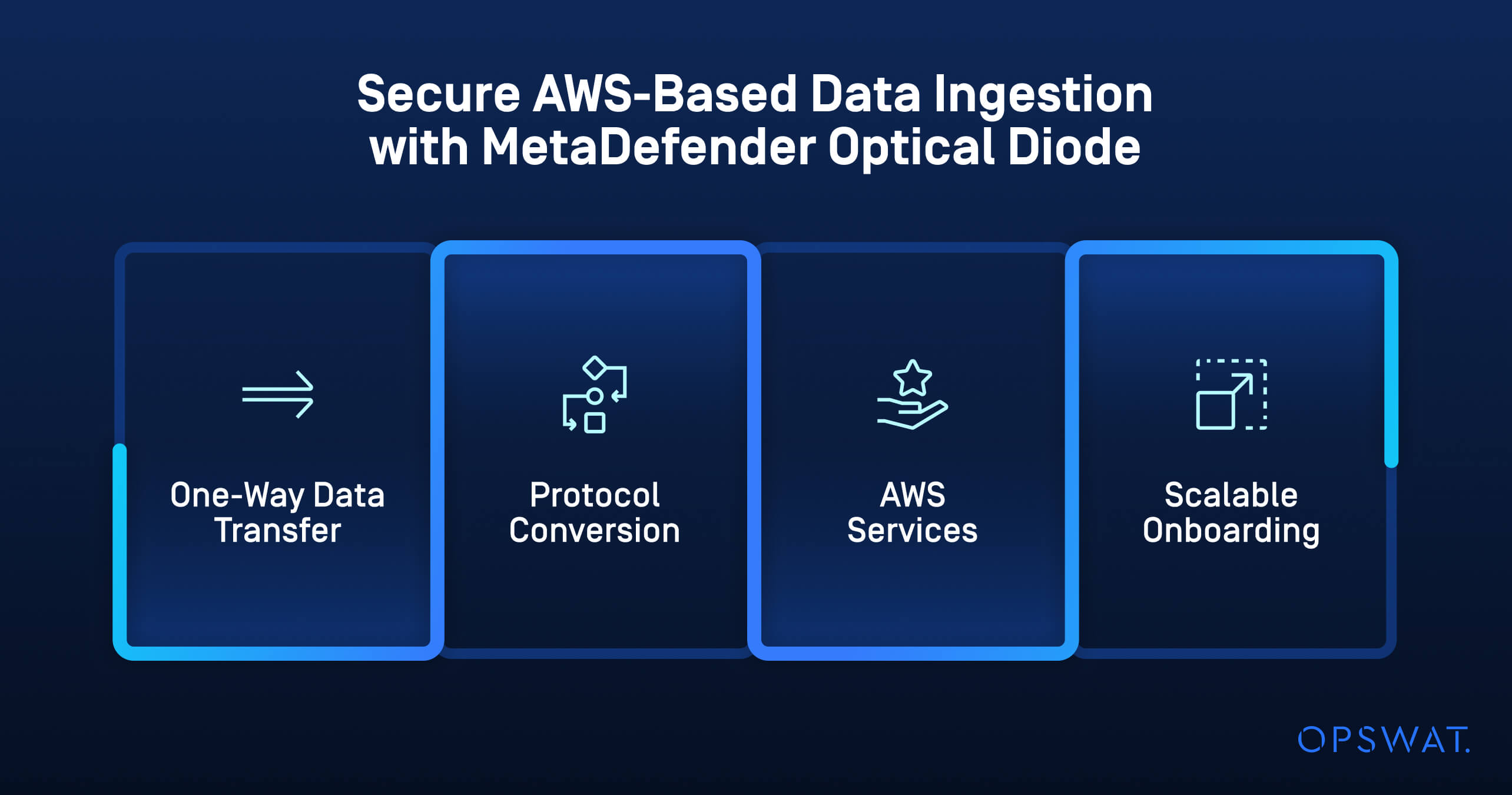

Die Architektur kombiniert physischen Schutz mit modernen Cloud-Diensten:

- Datenübertragung in eine Richtung: Die optische Isolierung garantiert, dass Daten nur aus der OT-Umgebung herausfließen. Malware, Ransomware und Angreifer können nicht eindringen.

- Protokollkonvertierung: Ältere Protokolle (z. B. Modbus) werden für eine nahtlose Cloud-Integration in moderne Formate wie MQTT umgewandelt.

- AWS-Dienste: Die Daten fließen in die AWS IoT-Services für die Aufnahme, das Hosting und den API , wobei AWS IoT Device Defender den Gerätezustand und die Konnektivität überwacht.

- Skalierbares Onboarding: Fend Cloud ermöglicht ein schnelles, konsistentes Onboarding von Legacy-IIoT-Geräten über mehrere Standorte hinweg.

Mit MetaDefender Optical Diode können wir AWS-Analysen nutzen, ohne alte OT-Ausrüstung zu ändern oder zu ersetzen, was Zeit, Kosten und Risiken spart.

Vizepräsident für Betrieb

Das Ergebnis: Echtzeit-Einblicke ohne Kompromisse bei der Sicherheit

Mit MetaDefender Optical Diode (Fend) hat der Hersteller das erreicht:

- Vollständige Cloud : Hardware Einwegkommunikation stellt sicher, dass keine externen Bedrohungen in Produktionsnetzwerke eindringen können.

- Betriebliche Einblicke in Echtzeit: Daten aus der Fabrik fließen sicher zu AWS-Analyseplattformen und unterstützen eine schnellere Entscheidungsfindung und vorausschauende Wartung.

- Erhaltene Betriebszeit: Ältere OT-Geräte bleiben unangetastet, wodurch kostspielige Ersetzungen oder riskante Upgrades vermieden werden.

- Stärkere Cybersecurity-Stellung: Die Lösung eliminiert Angriffsvektoren, die bei reinen Software- oder Direktverbindungsansätzen üblich sind.

- Angleichung an Bundesrichtlinien: Die Bereitstellung erfolgt gemäß den bewährten Verfahren von CISA, NIST SP 800-82r3 und DoD UFC 4-010-06.

Hardware einseitige Datenübertragung gab uns die Gewissheit, dass Bedrohungen nicht in unsere OT-Umgebung eindringen konnten, während unsere Teams die benötigten Einblicke erhielten.

Leiter IT-Sicherheit

Blick in die Zukunft

Dieses Projekt zeigt, dass Hersteller auf sichere Weise die Leistung der Cloud für bestehende Systeme nutzen können, ohne Cyber-Bedrohungen Tür und Tor zu öffnen. Mit der OPSWAT MetaDefender Optical Diode (Fend) und der AWS-Integration erhalten Betreiber kritischer Infrastrukturen die erforderlichen Einblicke, während der Betrieb widerstandsfähig, konform und sicher bleibt.

Sind Sie bereit, maßgeschneiderte, branchenführende Cybersicherheitslösungen für Ihre IT/OT-Umgebungen zu entdecken?